| triedgrutte | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | ||||

| d | |||||||||||||||||||

| P | triedsteek | grof | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | ||

| boete1 | - | - | - | - | - | - | - | - | 1 | 1.25 | 1.25 | 1.5 | 1.5 | 1.5 | 1.5 | ||||

| boete2 | - | - | - | - | - | - | - | - | - | 1 | 1.5 | - | - | 2 | 2 | ||||

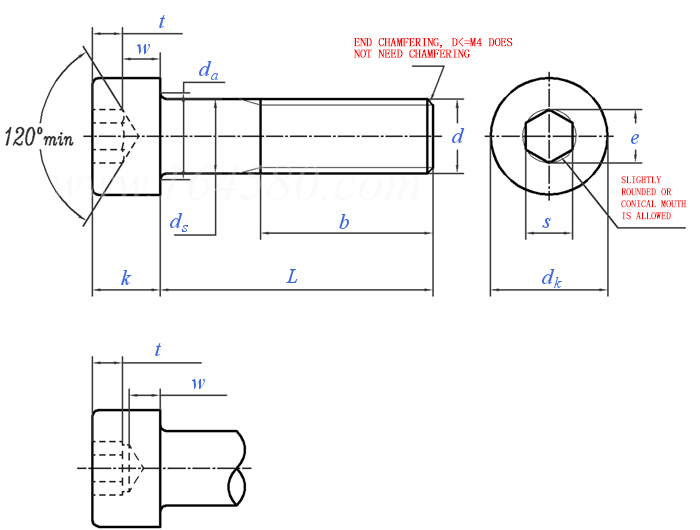

| dk | rûne kop | maks | 2.6 | 3 | 3.8 | 4.5 | 5.5 | 7 | 8.5 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 | ||

| gekartelde kop | maks | 2.74 | 3.14 | 3.98 | 4.68 | 5.68 | 7.22 | 8.72 | 10.22 | 13.27 | 16.27 | 18.27 | 21.33 | 24.33 | 27.33 | 30.33 | |||

| min | 2.46 | 2.86 | 3.62 | 4.32 | 5.32 | 6.78 | 8.28 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | ||||

| da | maks | 1.8 | 2 | 2.6 | 3.1 | 3.6 | 4.7 | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 20.2 | 22.4 | |||

| ds | maks | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | |||

| min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | ||||

| e | min | 1.5 | 1.73 | 1.73 | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 13.72 | 16 | 16 | 19.44 | |||

| k | min | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | |||

| min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.7 | 7.64 | 9.64 | 11.57 | 13.57 | 15.57 | 17.57 | 19.48 | ||||

| s | nominaal | 1.3 | 1.5 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 14 | 17 | |||

| min | 1.32 | 1.52 | 1.52 | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 | 14.032 | 14.032 | 17.05 | ||||

| maks | 1.36 | 1.56 | 1.56 | 2.06 | 2.58 | 3.08 | 4.095 | 5.14 | 6.14 | 8.175 | 10.175 | 12.212 | 14.212 | 14.212 | 17.23 | ||||

| t | min | 0.6 | 0.7 | 1 | 1.1 | 1.3 | 2 | 2.5 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |||

| w | min | 0.5 | 0.55 | 0.55 | 0.85 | 1.15 | 1.4 | 1.9 | 2.3 | 3 | 4 | 4.8 | 5.8 | 6.8 | 7.8 | 8.6 | |||

| 螺纹尺寸 | (M22) | M24 | (M27) | M30 | (M33) | M36 | M42 | M48 | M56 | M64 | M72 | M80 | M90 | M100 | |||||

| d | |||||||||||||||||||

| P | triedsteek | grof | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6 | 6 | 6 | 6 | |||

| Boete1 | 1.5 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | |||||

| Fine2 | 2 | - | - | - | - | - | - | - | - | - | - | - | - | - | |||||

| dk | rûne kop | maks | 33 | 36 | 40 | 45 | 50 | 54 | 63 | 72 | 84 | 96 | 108 | 120 | 135 | 150 | |||

| gekartelde kop | maks | 33.39 | 36.39 | 40.39 | 45.39 | 50.39 | 54.46 | 63.46 | 72.46 | 84.54 | 96.54 | 108.54 | 120.54 | 135.63 | 150.63 | ||||

| min | 32.61 | 35.61 | 39.61 | 44.61 | 49.61 | 53.54 | 62.54 | 71.54 | 83.46 | 95.46 | 107.46 | 119.46 | 134.37 | 149.37 | |||||

| da | maks | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 45.5 | 52.6 | 63 | 71 | 79 | 87 | 97 | 107 | ||||

| ds | maks | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 | ||||

| min | 21.67 | 23.67 | 26.67 | 29.67 | 32.61 | 35.61 | 41.61 | 47.61 | 55.54 | 63.54 | 71.54 | 79.54 | 89.46 | 99.46 | |||||

| e | min | 19.44 | 21.73 | 21.73 | 25.15 | 27.43 | 30.85 | 36.57 | 41.13 | 46.83 | 52.53 | 62.81 | 74.21 | 85.61 | 97.04 | ||||

| k | maks | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 | ||||

| min | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 41.38 | 47.38 | 55.26 | 63.26 | 71.26 | 79.26 | 89.13 | 99.13 | |||||

| s | nominaal | 17 | 19 | 19 | 22 | 24 | 27 | 32 | 36 | 41 | 46 | 55 | 65 | 75 | 85 | ||||

| min | 17.05 | 19.065 | 19.065 | 22.065 | 24.065 | 27.065 | 32.08 | 36.08 | 41.08 | 46.08 | 55.1 | 65.1 | 75.1 | 85.12 | |||||

| maks | 17.23 | 19.275 | 19.275 | 22.275 | 24.275 | 27.275 | 32.33 | 36.33 | 41.33 | 46.33 | 55.4 | 65.4 | 75.4 | 85.47 | |||||

| t | min | 11 | 12 | 13.5 | 15.5 | 18 | 19 | 24 | 28 | 34 | 38 | 43 | 48 | 54 | 60 | ||||

| w | min | 9.4 | 10.4 | 11.9 | 13.1 | 13.5 | 15.3 | 16.3 | 17.5 | 19 | 22 | 25 | 27 | 32 | 34 | ||||

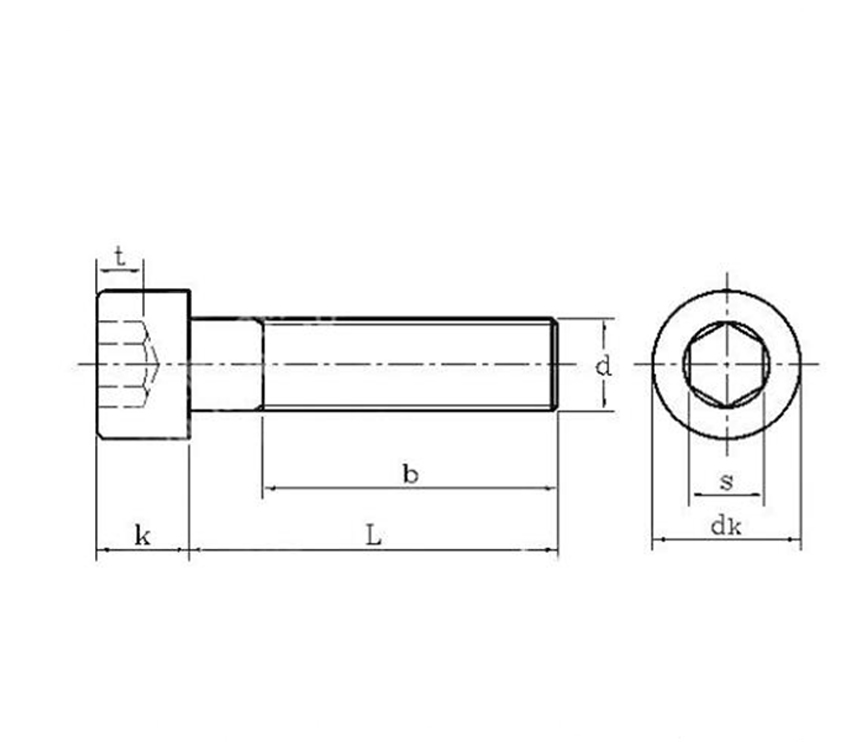

PRODUKTEN DETAILS:

Oer it algemien makke fan SUS304 roestfrij stieldraad. Der binne twa soarten roestfrij stielen hexagonskroeven yn omloop op 'e merk: mei in knurlingkop en sûnder knurlingkop.Rustfrij stielDe kwaliteit fan it materiaal kin oer it algemien net bepaald wurde troch it produksjeproses fan 'e skroef fan in hex-socket (ûnderfining yn 'e sektor, allinich ter referinsje): oer it algemien kin de rjochte proses fan in hex-socket-skroef fan roestfrij stiel beskôge wurde as in autentike SUS304-produksjeskroef.Rustfrij stielSeksinskroeven sûnder kryptonyt op 'e kop kinne beskôge wurde as wat minderweardich materiaal of produkten mei in leger nikkelgehalte. De spesifike analyze is lykwols ûnderwurpen oan it rapport útjûn troch de kwaliteitsynspeksje-ienheid.

In roestfrij stielen hexagon-skroef is in soarte gatskroef, dy't oer it algemien brûkt wurdt yn masine-arkapparatuer, gemyske apparatuer, wetterpompen, skippen, enerzjy-apparatuer en oare plakken. In folsleine tosk roestfrij stielen hexagon-skroef wurdt faker brûkt, en in heale tosk roestfrij stielen hexagon-skroef wurdt yn húshâldlik gebrûk faker brûkt yn eksportapparatuer. It materiaal is ferdield yn twa soarten: SUS304 roestfrij stielen hexagon-skroef, sterkteklassebeskriuwing -A2-70. Hexagon-skroeven, SUS316 roestfrij stiel, sterkteklassebeskriuwing -A4-70.

FABRYK EN FERPAKKING:

WY BINNE OP DE BEFESTIGINGSMIDDELENBEURS:

-

Hege kwaliteit roestfrij stielen trieddanker

-

U-bout Hardware U Type / U Type Fundament Anker ...

-

Fabryksfoarsjenningsbefestigingen koalstofstiel anty-slip ...

-

Liftgebou koalstofstiel sinkplatearre boutanker

-

Anker fan hege kwaliteit mei heksagonale bout

-

Mouw Anker Bolts heak Bolts Fan Izer Materiaal ...